Bulk Bags General Guidelines:

Before getting started, here are some general guidelines to adhere by:

- Make sure you have the right FIBC – while all FIBCs may look the same at first glance, there are many differences tailored for specific applications. Some of these include the fabric material and strength, special coatings or liners, as well as additional features such as filling/discharge options and various lifting loop styles. To ensure you have the right bag for your operation, Bagwell is happy to offer our expertise and consultation.

- Different products (e.g. food products, dangerous/hazardous goods, pharmaceuticals) have different regulatory requirements for packaging. Make sure that the FIBC you choose is approved for and compatible with your products.

- For safety reasons, it is strongly recommended that you do not use any bulk bags that have been damaged. If this is unavoidable, please consult a member of the Bagwell staff first to ensure that it is safe to do so.

- Follow all the instructions outlined on the Safe Handling Tag, which can be found on the top edge of all Bagwell bulk bags. Most notably, please note the Safe Working Load, which must not be exceeded under any circumstances.

- Lastly, follow the applicable regulatory and safety requirements outlined by regional and federal governing bodies.

Getting Started:

First, make sure that your lifting device, whether that’s a forklift, crane, or hoist, is designed to handle bulk bags and is rated for the maximum weight of the filled FIBC. If you are unsure whether your lifting device is appropriate, please reach out to the Bagwell team for assistance.

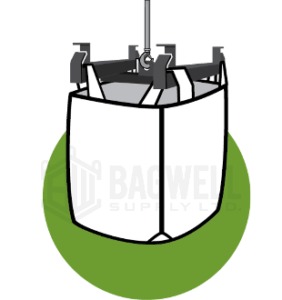

Always use all lifting loops provided – in most cases, bulk bags have 4 lifting loops, one on each corner. Do not gather all 4 loops and lift from a single point, unless the bag has been specifically designed to do so. When lifting from a crane or hoist with a single hook, we recommend that you use a crane adapter. A crane adapter allows for the bag to be lifted vertically on all the loops, as opposed to from a single point, which allows the force on the bag to be evenly distributed.

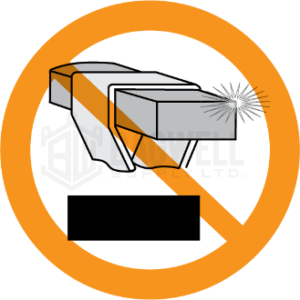

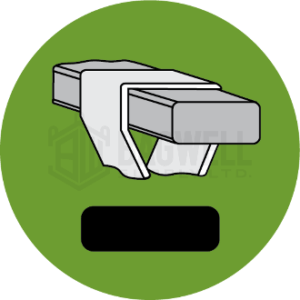

In addition, conduct a thorough inspection of the forklift tines, crane hooks, bars or other handling devices to make sure there are no sharp edges or protrusions that can damage the loops. The edges of the forklift tines should be sufficiently rounded or have a protective covering if the edges are sharp. If you’re working with pallets, also do an inspection of the pallet for protruding nails or splinters. Adjust the width of the forks accordingly to allow for a seamless vertical lift and to avoid applying lateral forces on the bag.

Carrying a Filled Bulk Bag Using a Forklift

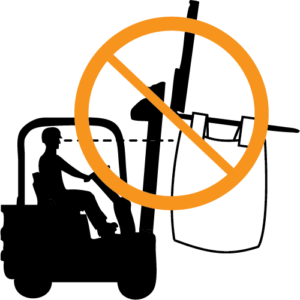

Now that you’ve done your checks and made the proper adjustments, you are ready to get started on the forklift. Be mindful to not make sudden stops or lifts while carrying the bulk bag. Make sure the bag is clear of the ground to prevent dragging and contact with the forklift wheels. Keep the mast slightly tilted upwards with the bag close to the mast to keep it from falling off the forks. Most importantly, make sure that the positioning of the bag does not obstruct the forklift operator’s field of vision. Keep speed moderate, as the added weight can cause instability especially when making sharp turns.

The above picture shows the correct way to carry a bulk bag with a forklift. The bag is elevated sufficiently off the ground while not obstructing the operator’s field of vision. The forks are tilted slightly upward.

Filling Up a Bulk Bag

Lay the bulk bag’s base flat on a flat platform or pallet, and if the bag has a discharge bottom, ensure that it is closed before filling. Use available support devices to hold the bag in place, or if needed have workers hold the loops if it is safe to do so. In some cases, it may help to inflate the bag with air prior to filling so that it is filled more evenly. Depending on the product filled, the height of the bag should be less than 2.5 times the width of the bag; however, for dangerous goods/hazardous substances, the filled bag’s height should not be more than 2 times the width of the bag. This is a good rule of thumb to quickly determine if your bag has been evenly filled.

Once the bulk bag has been filled, take the time to ensure that the top is properly secured if it is not an open-top bag.

Each bulk bag’s Safe Working Load (SWL) can be found written on the bag. For Bagwell bags, this is found on the Safety Handling Tag, which is attached to the top edge of the bag (see below for a sample). Do not exceed this under any circumstances.

Bagwell FIBC Handling Tag – Sample

Discharging Bulk Bags

Bagwell’s bulk bags have a variety of discharge options. For bags that have a flat bottom, discharge the bag by making a cut across the bottom of the bag. Make sure to exercise caution and do not stand directly under the bag. For bags with discharge spouts, gradually open the closure, allowing the material to flow out at a steady stream.

Do not stand under suspended bulk bags and keep all appendages clear of the space between the bag and the ground.

For more information see the FIBC Safe Handling Guidelines

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt. Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur, vel illum qui dolorem eum fugiat quo voluptas nulla pariatur?

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt. Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur, vel illum qui dolorem eum fugiat quo voluptas nulla pariatur?